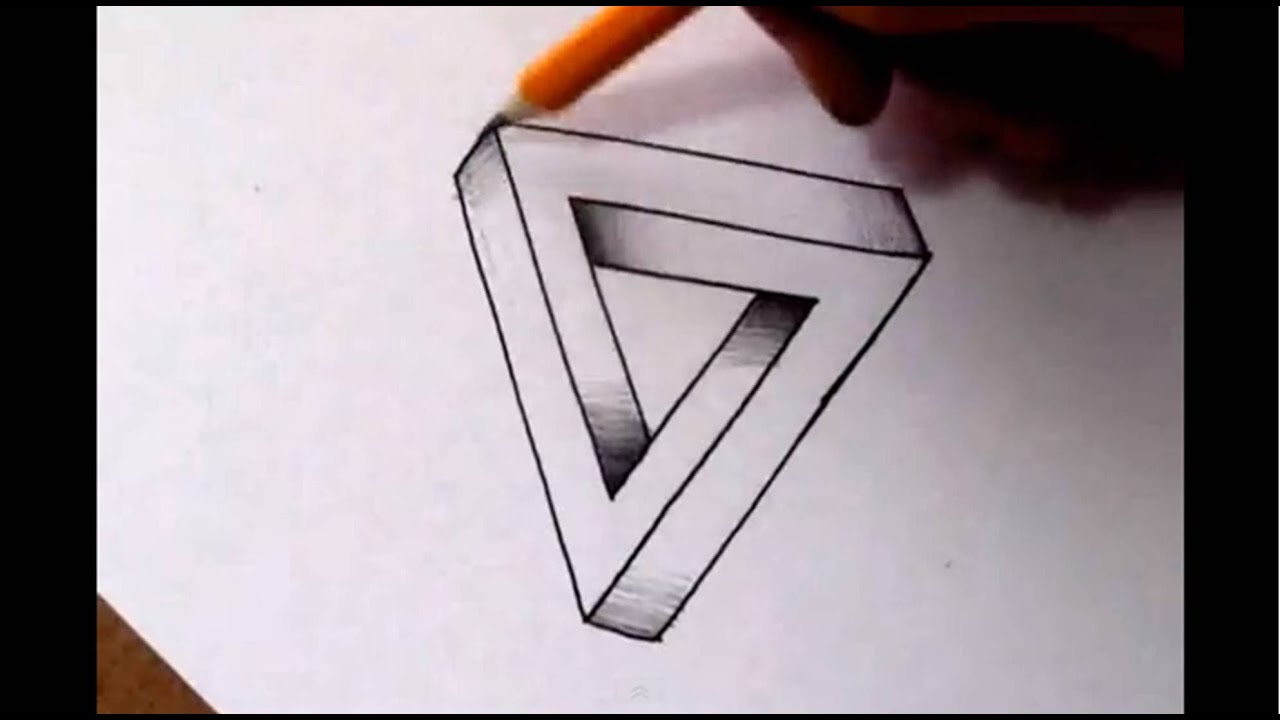

This combination of properties cannot be realized by any three-dimensional object in ordinary Euclidean space. The beams may be broken, forming cubes or cuboids. The tribar/triangle appears to be a solid object, made of three straight beams of square cross-section which meet pairwise at right angles at the vertices of the triangle they form. At the moment of illusion, there appears to be a pair of purple faces (one partially occluded) joined at right angles, but these are actually parallel faces, and the partially occluded face is internal, not external. Now, lotus will prove again to the world the edge that 3D-printing will offer to the construction industry when it comes to free-form structures”.A rotating Penrose triangle model to show illusion.

Gandhi further said, “But we have already proved with our Ganesha temple that shapes that are almost impossible to attain with conventional techniques can be done easily using 3D technology. He added, “We are hoping that what we learned from the ‘modak’ will let us finish the ‘lotus’ earlier than that”. Jeedipalli stated, “With the Shivalay and the modak completed, phase II comprising the Lotus and the tall spires (gopurams) are underway”.Īccording to Gandhi, the dome-shaped modak was challenging to print, but the team accomplished it in six hours over ten days. The team is now constructing a temple for Goddess Parvati that is designed like a lotus. This construction takes care of the structural requirements, principles of temple design, 3d printing requirements while dealing with the challenges of in-situ construction”. Gandhi stated, “This structure demonstrates Simpliforge’s ability to print 51° and 32° in outward and inward cantilever, respectively while printing in-situ catering to the architectural and aesthetic requirements. After undergoing load testing and evaluation for functional use, it is now being used as a pedestrian bridge in the garden around the temple”. The concept and design were developed and evaluated by Prof K V L Subramaniam and his research group from the civil engineering department of IIT Hyderabad. While discussing the 3D-printed temple, the CEO of Simpliforge Creations, Dhruv Gandhi, said, “This was also assembled on-site at Charvitha Meadows, Siddipet. Simpliforge Creations and the Indian Institute of Technology, Hyderabad, constructed India’s first prototype bridge in just under two hours in March. From start to finish, the 3D structure is anticipated to take 2-3 months, whereas the conventional building would have required more than double the time.

The construction of this temple is expected to be finished in July. He added, “Completely printed on-site, the temple’s dome-shaped structures presented formidable challenges that required the team to employ bespoke design techniques, meticulous analysis, and innovative construction methods while following the principles of temple architecture resulting in this awe-inspiring architectural marvel”. The MD of Apsuja Infratech, Hari Krishna Jeedipalli, said, “The three sanctums, or garbhas, within the structure represent a ‘modak’, dedicated to Lord Ganesha a Shivalay, a square abode devoted to Lord Shankar and a Lotus shaped home for Goddess Parvati”. Construction 3D printing is a method for manufacturing construction elements or entire buildings by means of a 3D printer printing concrete, polymer, metal, or other materials, layer-by-layer. Simpliforge prints the structure using an internal system, locally produced materials, and software.

Simpliforge provides manufacturing solutions to Apsuja to facilitate the construction of this temple by providing 3D printing. The facility is also believed to be the largest in South Asia also. The company claims to have India’s first robotics construction 3D printing facility. The Hyderabad-based construction company Apsuja Infratech will construct this 3D-printed temple in collaboration with Mumbai-based 3D-printed construction company Simpliforge Creations. This temple will be a three-part structure constructed on an area of 3800 square feet and 30 feet tall. The temple will be situated in Burugupally village under Siddipet municipality in Charvitha Meadows, a gated villa community. The world’s first 3D-printed Hindu temple will reportedly be built in Telangana.

0 kommentar(er)

0 kommentar(er)